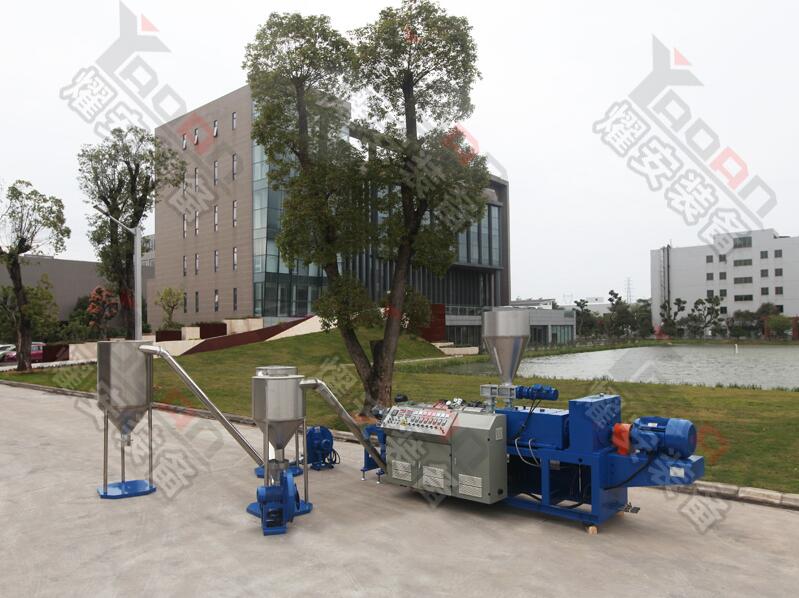

Air-cooled granulation equipment

|

|

1: The device consists of a high speed mixer, mixer, automatic hopper, granulator, centrifugal cyclone, vibrating screen distribution, storage tank composed of chemical raw materials to achieve the automatic integration granulation. Because of the different characteristics of the compound, there are different ways granulation, the granulated industry applications more modes are: a twin-screw granulation, granulation air-cooled, water-cooled granulation, spray granulation, water strand pelletizing, etc. , it is common in several granulation production.

2: The low shear, high mixing screw design ensures high granulation production run, and always stable basis and the pellets evenly full, mellow color.

Multicomponent dosing system ensures configuration masterbatch materials more easily and effectively with the precision cutter ensures smooth section.

3: imported frequency adjustment, better adapted to the different granulation process speed. Material quality carbon Gang, and after a hard bake process, the mold naturally durable. Reasonable distribution of the flow channel outlet, ensures uniform extruded pellet independently of each other. Unique three-dimensional structure of cooling, the cooling more efficient, combined with the new multiple-powered fan to cool ideas, so good quality grain family is guaranteed.

|